What is the normal range of brightness and dark spots for the AU LCD screen

Date:2025-05-15

1.Scope:

1.1 The incoming inspection standards shall be applied to TFT-LCD Modules (hereinafter called ""Modules"") thatsupplied by AU Optronics Corporation (hereinafter called "“seller"").

1.2 Specifications contains

Electrical inspection specification

Appearance specification

Outside dimension specification

2.Inspection sampling method:

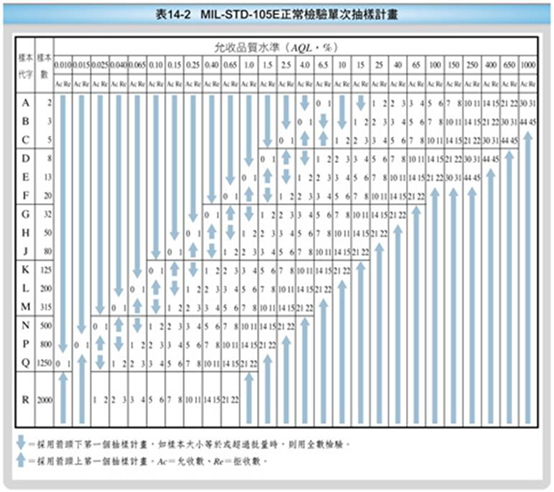

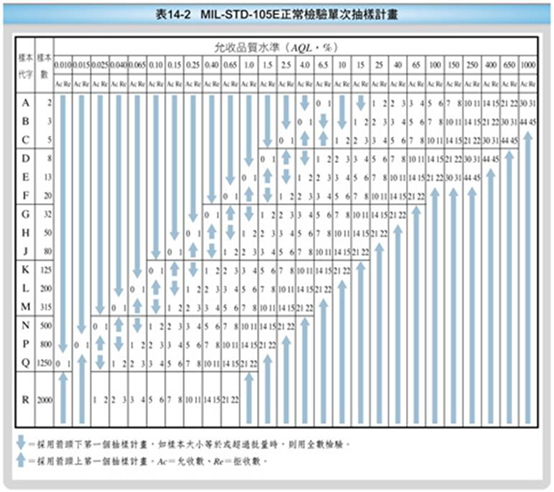

Unless otherwise agree in writing, the method of incoming inspection shall be based on MIL-STD-105E

2.1 Lot size: Quantity per shipment lot per model.

2.2 Sampling type: Normal inspection, single sampling.

2.3 Sampling level: Level ll.

2.4 Acceptable quality level (AQL):

Major defect: AQL=1.0%.

Minor defect: AQL=2.5%

Rig.1:Inspection Sampling standard for MIL-STD.105E :

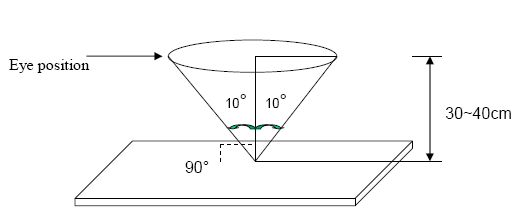

Rig.2 Incoming inspection judgment method :

3. Inspection instruments:

3.1 Pattern generator: LD2000 or equivalent model.

3.2 Video board: AU video board or equivalent. The output of the signal should comply with the specification provided by AU.

3.3 Luminance colorimeter: Topcon BM -7 or equivalent model

4. Inspection environment conditions:

4.1 Room temperature : 20 ~ 25°C

4.2 Humidity:65±5% RH

4.3 llumination: Fluorescent light (Day-Light Type) display surface illumination to be 300~700 lux (standard 500lux )

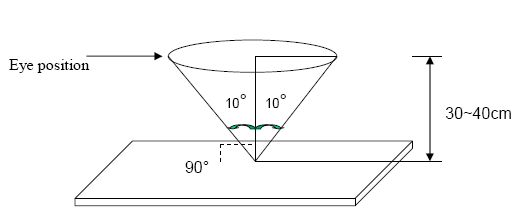

4.4 To be a distance about 35±5cm in front of LCD unit, viewing line should be perpendicular to the surface of the module judge the visual appearance with human‘s eyes.(±10° viewing edge will be allowed)

4.5 Take off the protector of polarizer while judging the display area.

4.6 If there is any question while judging, check the panel again while operating.

5. Classification of defects:

Defects are classified as major defects and minor defects according to the degree of defectiveness defined herein.

Major defects:

A minor defect is either a defect that is not likely to reduce materially the usability of the product for its intended purpose, or a departure from an intended purpose with little bearing on the effective use or operation of the product.

5.1 Electrical inspection specification

Inspection Item | Specification |

Line defect | Not allowed |

Bright dot | ≤2dots |

Dark dots | ≤3dots |

Total dots defect | ≤5dots |

Continuous defect | Two continuous bright dots : | NA |

Over three continuous bright dots(vertical, horizontal, oblique) : | Not allowed |

Two continuous dark dots (vertical, horizontal, oblique) : | ≤1pair |

| Over three continuous dark dots (vertical, horizontal, oblique) : | Not allowed |

| Two continuous dark dot and bright dot (vertical, horizontal, oblique) : | ≤1pair |

| Over three continuous dots (vertical, horizontal, oblique) : | Not allowed |

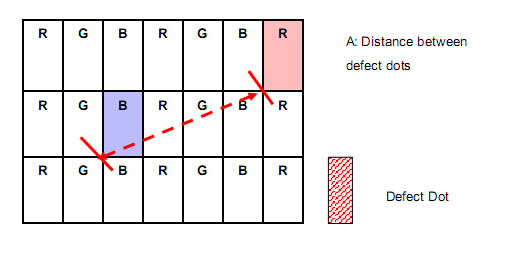

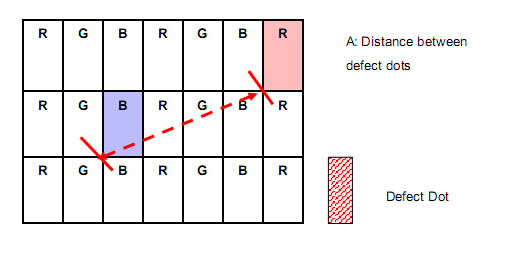

| Distance between 2 Bright dots : | ≥5mm |

| Distance between 2 Dark dots : | ≥5mm |

| Distance between Dark dotand Bright Dot | ≥5mm |

Mura |

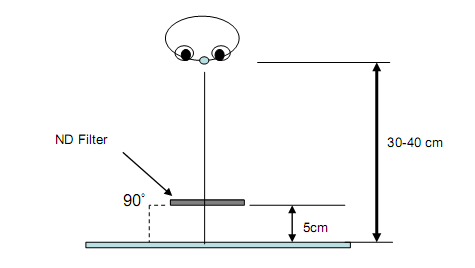

| Can‘t be seen via 5% ND filter or judge by equivalent sample (JND2.5) |

Note 1)Judgment criteria (For Bright dot and Small Bright dot) : Using 5% ND Filter,If dot defect could be observed,

it is defined as one bright dot . If dot defect could not be observed, it is defined as small bright dot.

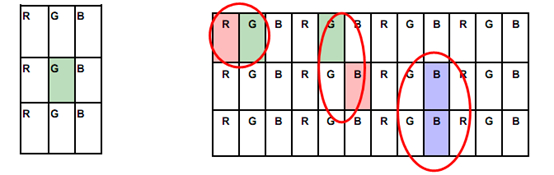

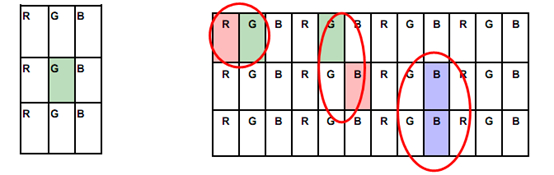

The amount of small bright dots which are invisible through 5% ND filter should be less or equal to 10. Definition of two continuous dots: Only for two continuous dots,including vertical, horizontal, oblique type.The continuous dots should be observed under the same displaypattern in any one of Black/White / Red/Green/Blue pattern.

*Inspection pattern: Standard inspection patterns of dot defect are listed below. AU uses these patterns as standard criteria for judging dot defect. Please inform AU if any other pattern is used to examine dot defect.

Test Pattern | Defect |

Black | For bright dot(s) |

White | For dark dot(s) |

Red | For bright and dark dot(s) |

Green | For bright and dark dot(s) |

Blue | For bright and dark dot(s) |

Note 3) Defect criteria diagram

Dot defect diagram

One dot (Bright /Dark) Two continuous dots(Bright/Dark)

Definition of distance between defect dots as following

Note 4) In three (or more) adjacent dot defect, for any 3rd dot that adjacent to 2 continuous defective dots (can be of any combination of bright dots and dark dots), the 3rd dot, no matter how large it may be, should be viewed as a dot.

Note 5) Unless other specified written document or limit samples, Mura (display un-uniformity) should be inspected under the 5% ND filter and be acceptable when it is invisible.

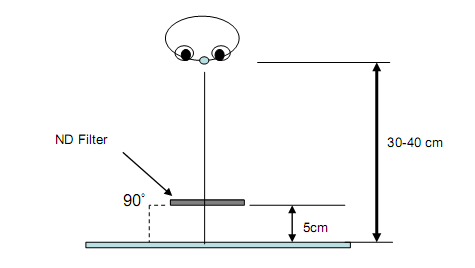

ND filter use method: The inspection method of ND Filter-holding ND filter in front of the panel around 5 cm and examine the panel from 35¡À5 cm in the front view for 3 seconds.

Note. 6) While operating over 50℃ ambient temperature , there should be no function failure occur and Mura (display un-uniformity) should be invisible under 1% ND filter applied.

Note 7) Image Retention : 5 seconds test pattern and image retention must be disappeared in 5 seconds after pattern changed.

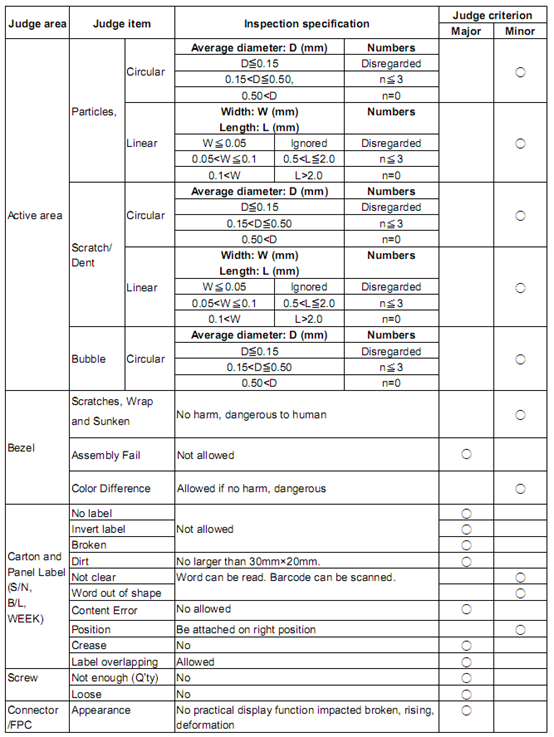

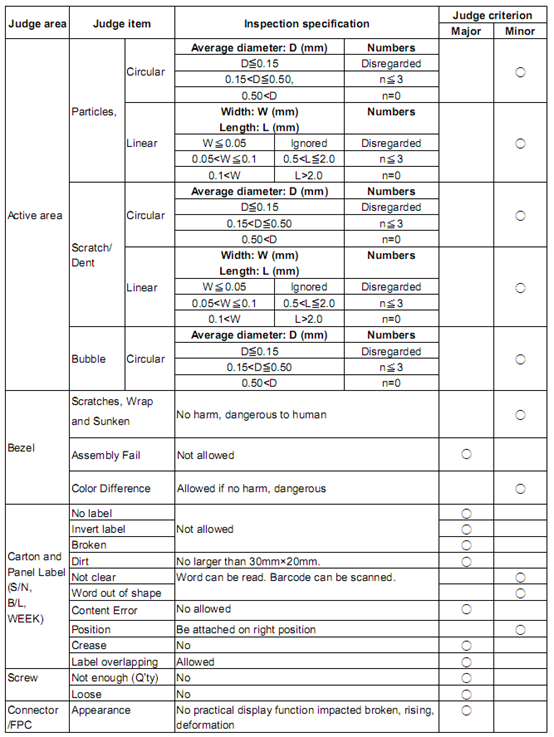

6.2 Appearance inspection specification

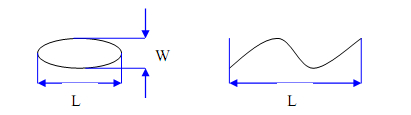

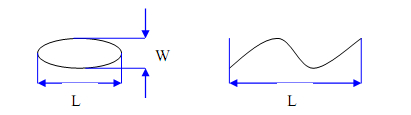

Note 1 : When L≥2W, defect count as liner defect.

Note 2: D=(W+L)/2

Note 3 : Extraneous substances which can be wiped out, such as fingerprint and particles are not considered as a defect.

Note 4: Defects on the Black Matrix (outside Active Area 0.3mm) are not considered as a defect.

6. Inspection judgement

6-1 The judgement of the shipped lot (acceptance or rejection) should follow the sampling plan of MIL-STD-105E, single sampling, normal inspection, level II.

6-2 If the number of defects is equal to or less than the applicable acceptance level, the lot

shall be accepted.

6-3 If the number of defects is more than the applicable acceptance level, the lot shall be

rejected and the buyer should inform the seller of the result of incoming inspection in writing

AUO LCD DISPLAY:https://www.auo-lcd.com/products/auo-lcd-screen/