What is a resistive touch screen?

Date:2025-11-07

What is a resistive touch screen?

Core Definition: A Pressure-Sensitive Screen

A resistive touch screen is a type of touch-sensitive display that operates by sensing physical pressure applied to its surface. It is one of the oldest and most reliable touch technologies, widely used in environments where durability, low cost, and flexibility are key.

How It Works: The Simple Physics Behind It

The fundamental principle is straightforward: Two conductive layers are separated by a tiny gap. When you press, they touch, completing a circuit.

Imagine it like this: Think of a sandwich with two flexible, conductive sheets, separated by tiny, invisible spacer dots.

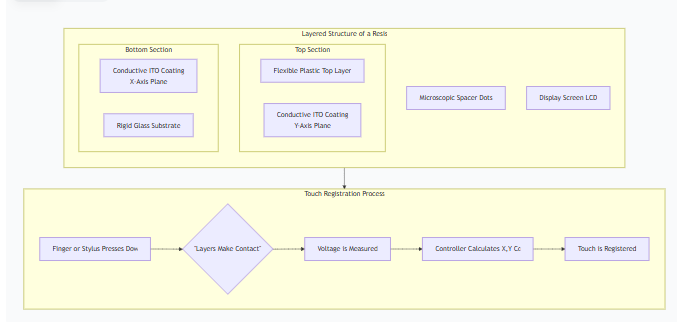

The Layers: A typical resistive screen has two thin, transparent, electrically resistive layers:

The Coating: The inner surfaces of both layers are coated with a transparent conductive material, most commonly Indium Tin Oxide (ITO).

The Spacers: Microscopic insulating spacer dots are placed between the two layers to keep them separated when not in use.

The Voltage Gradient: Electrodes are attached to the layers to create a uniform voltage gradient across each one (one layer for the X-axis, the other for the Y-axis).

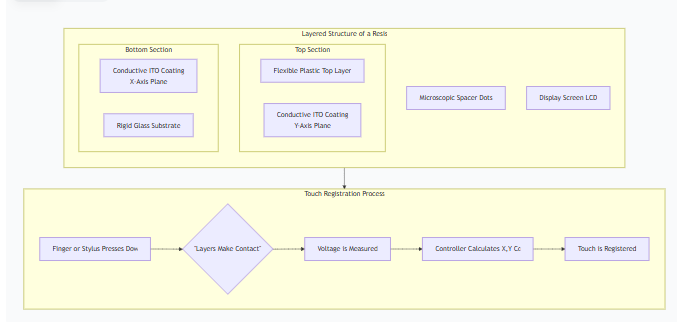

Here is a visual breakdown of this layered structure and how a touch is registered:

When you press the screen with a finger, stylus, or any other object (even with gloves on), the flexible top layer bends inward. The two conductive ITO layers make contact at the precise point of pressure.

The controller chip attached to the screen measures the voltage at that contact point. Since each layer has a specific voltage gradient, the controller can precisely calculate the X-coordinate from one layer and the Y-coordinate from the other, pinpointing the exact location of your touch.

Key Advantages (Why You Would Choose One)

Cost-Effective: Very inexpensive to manufacture, making them ideal for budget-friendly devices.

Can Be Used with Any Object: They respond to pressure, so you can operate them with a finger, gloved hand, stylus, pen, or even a fingernail. This is their biggest advantage in many industrial and medical settings.

High Durability & Resistance:

Dust and Water Resistant: The solid top layer is effective at sealing out minor moisture, light rain, and dust, often allowing them to meet IP65 standards.

Resistant to Surface Contaminants: Grease, oil, and dirt on the screen do not affect its functionality.

Good Accuracy: Offers high positional accuracy for single touches, which is why they were historically popular with styluses for PDAs.

Key Disadvantages (Their Limitations)

Poor Optical Clarity: The multiple layers and the air gap between them lead to increased reflection and reduced light transmission (often around 75-85% compared to ~90%+ for capacitive screens). This results in a dimmer image that can look "washed out."

Lower Durability (Physical): The flexible top layer is made of plastic and can be scratched or punctured by sharp objects. It is also susceptible to damage from vandalism.

No Multi-Touch: Traditional 4-wire and 5-wire resistive screens cannot detect more than one touch point at a time. While some advanced matrix resistive screens can, it's not common.

Requires Firm Pressure: You need to apply a deliberate press to deform the layers. Light, swiping gestures (like those on a smartphone) do not work well and can feel unresponsive.

Wear Out Over Time: The constant flexing of the top layer can cause the ITO coating to develop micro-cracks over millions of presses, leading to "dead zones" or inaccurate readings.

Common Applications

Due to their unique advantages, resistive touchscreens are still the preferred choice in many specific fields:

Industrial Controls: Factory automation, machine control panels (where operators wear gloves).

Medical Equipment: Hospital devices, diagnostic instruments (for hygiene and glove compatibility).

Point-of-Sale (POS) Systems: Restaurant kiosks, payment terminals.

Older PDAs, GPS Devices, and Smartphones: (Most pre-iPhone touchscreen phones used resistive technology).

Signature Pads: Where a stylus is required.

Summary: Resistive vs. Capacitive (The Modern Alternative)

Feature | Resistive Touchscreen | Capacitive Touchscreen |

Activation Method | Pressure | Electrical Conductivity (human touch) |

Input Method | Any Object (finger, glove, stylus) | Finger or Capacitive Stylus only |

Multi-Touch | Rarely | Standard |

Optical Clarity | Poorer (dimmer, more reflective) | Excellent (brighter, clearer) |

Durability | Good against liquids/dust, but scratchable | Hard glass surface is more scratch-resistant |

Cost | Low | Higher |

Best For | Industrial, medical, cost-sensitive, gloved use | Consumer smartphones, tablets, modern UIs |

In conclusion, a resistive touch screen is a versatile, pressure-sensitive technology prized for its low cost, ability to work with any input, and resilience in harsh environments, but it sacrifices the brilliant visuals and multi-touch capability of its capacitive counterpart.