How to lower the operating temperature of the LCD screen?

Date:2025-12-18

How to lower the operating temperature of the LCD screen?

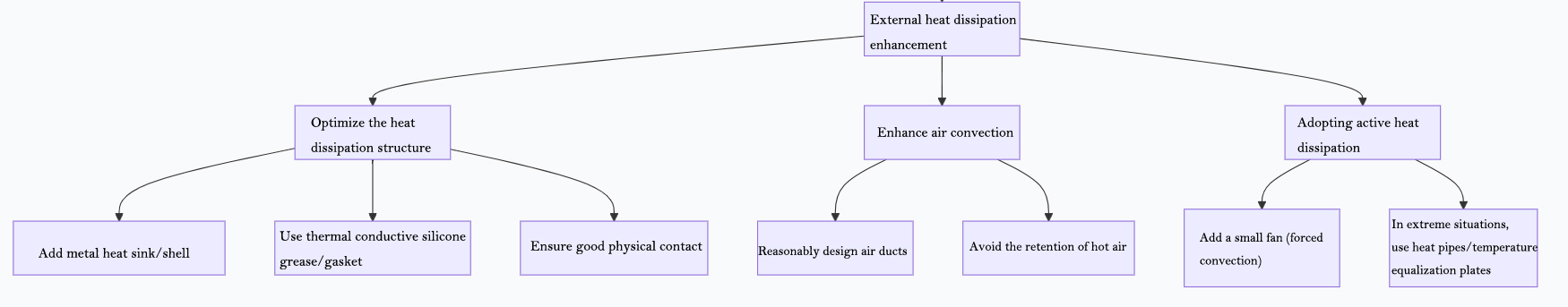

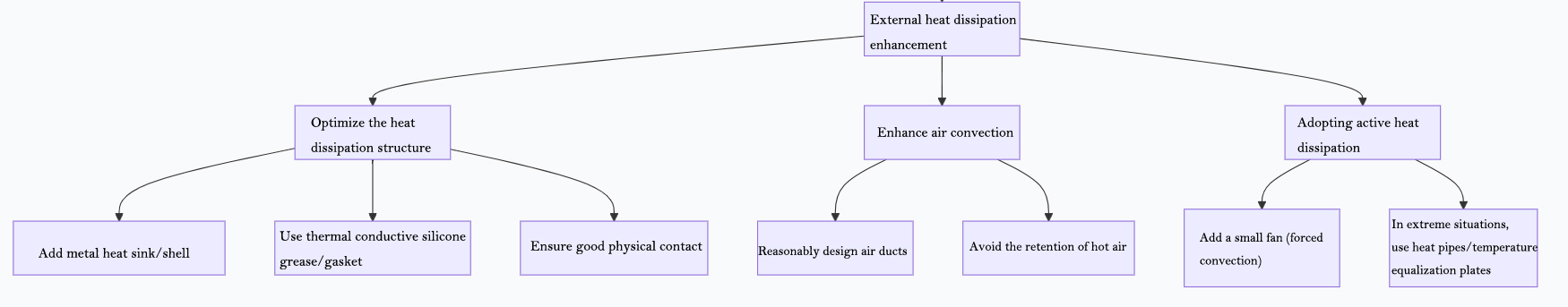

The core idea for reducing the operating temperature of LCD screens is to optimize heat dissipation, reduce heat generation, and select more heat-resistant components. This is a system engineering, and the following figure outlines the complete strategy framework from external heat dissipation to internal optimization:

The above figure shows a systematic cooling strategy, and the following are the specific operations and explanations of the key points:

Detailed explanation of core measures

1. External heat dissipation enhancement: basic and critical

Add heat sinks: Paste aluminum or copper heat sinks on the screen driver IC and backlight LED areas (usually metal backplates), which is low-cost and has direct effects.

Improve heat conduction: Use thermal grease and thermal pads between the heating components and the heat sink/housing to fill the gaps and enhance heat conduction efficiency.

Optimize mechanical design: Ensure tight contact between heat dissipation components and avoid air insulation layers.

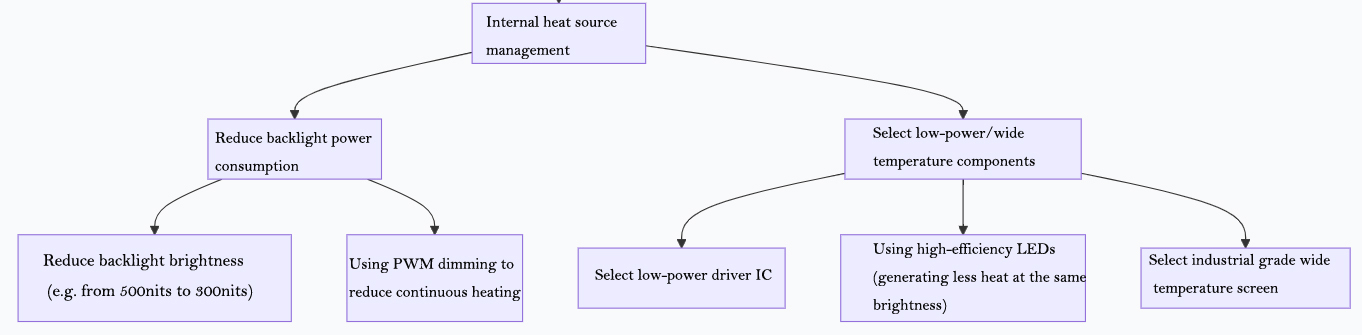

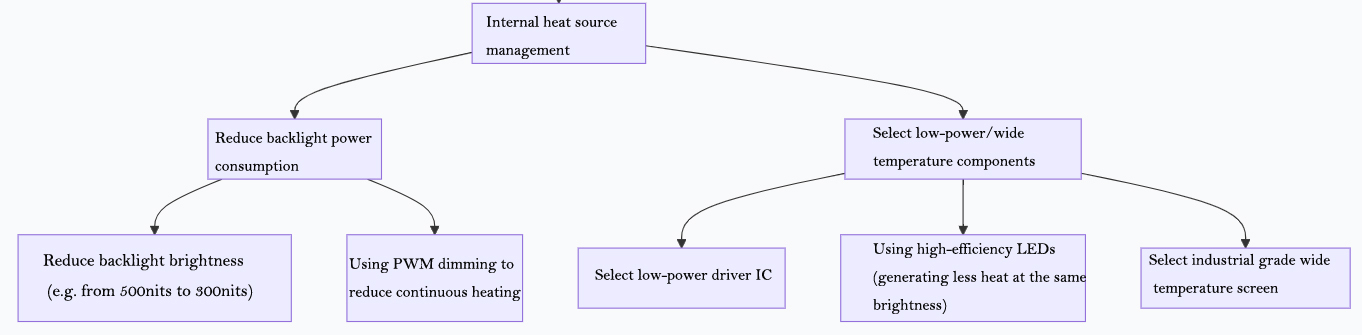

2. Internal heat source management: reducing burden from the source

Reduce backlight power consumption: Backlight is the largest heat source. On the premise of meeting the demand, reducing the brightness appropriately (such as from 500nit to 300nit) can significantly cool down. PWM dimming is more efficient than DC dimming.

Select efficient/wide temperature components: Clearly state the requirements during procurement:

High luminous efficiency LED: Higher luminous efficiency, less heat generation under the same brightness.

Industrial grade wide temperature screen: Although it is more expensive, the liquid crystal, polarizer, adhesive materials used in it have better heat resistance, which improves thermal stability from the source.

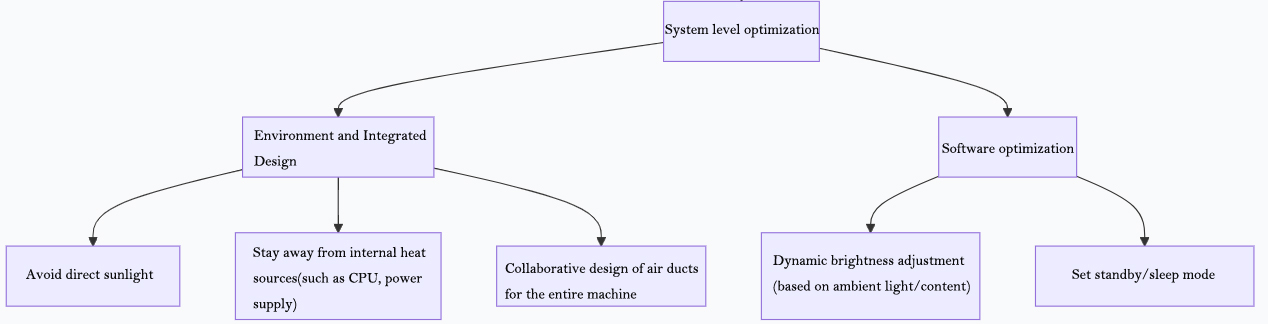

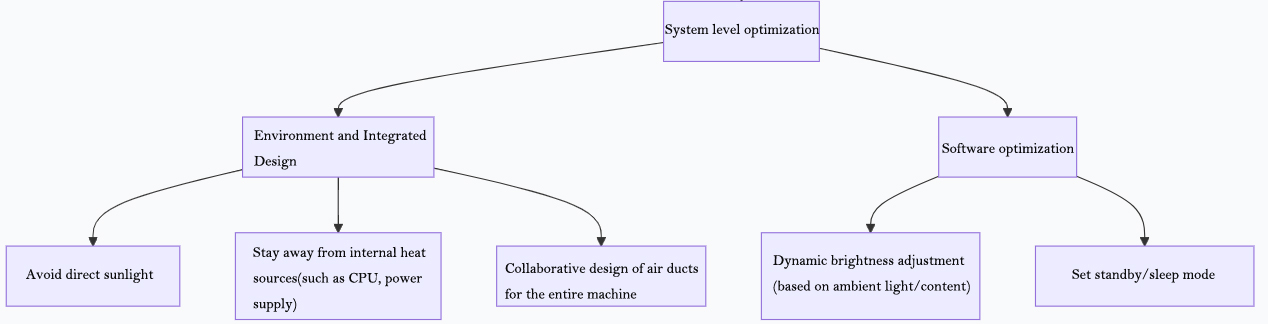

3. System level optimization and environmental control

Collaborative cooling of the whole machine: Design air ducts with the screen as part of the whole machine's cooling system to avoid installing it above large heat sources such as CPUs and power modules, and to prevent hot air from being trapped.

Software intelligent adjustment: Develop dynamic backlight control function, automatically adjust brightness according to display content (such as when most areas are dark) or environmental temperature.

Improve the usage environment: Avoid direct sunlight on the screen and maintain good ventilation around the device.

Important precautions

Measurement first: Use thermocouples or infrared thermal imagers to locate specific "hotspots" (usually driver ICs, LED light bar positions) in order to dissipate heat in a targeted manner.

Comprehensive strategy: The effectiveness of a single method is limited, and a combination of the above structure, components, and software is needed.

Reserved margin: The design target temperature should be at least 10 ° C lower than the maximum operating temperature specified in the LCD screen specification to ensure long-term reliability and lifespan.

If you can provide more details about the specific application scenarios of the screen (such as outdoor devices, enclosed spaces), size, power consumption, or current temperature issues, I can analyze more targeted solutions for you.

AUO LCD DISPLAY:https://www.auo-lcd.com/products/auo-lcd-screen/