How to choose an industrial LCD screen with appropriate working temperature?

Date:2025-09-29

Selecting a suitable working temperature LCD screen for industrial equipment is a key step in ensuring long-term stable and reliable operation of the equipment. The industrial environment is complex and variable, and insufficient temperature adaptability can lead to abnormal screen display, sudden reduction in lifespan, and even direct damage.

The core of selecting the working temperature for industrial LCD screens lies in accurately matching the actual environmental temperature of the device deployment and reserving sufficient safety margins.

1. Core principle: Understand the difference between standards and industrial grade

Firstly, it is important to recognize the significant temperature difference between consumer grade screens and industrial grade screens

Commercial/consumer grade: typically 0 ° C~50 ° C or -10 ° C~60 ° C. Suitable for temperature controlled environments such as offices and homes.

Industrial grade: The range is much wider, with a common range of -30 ° C to 80 ° C. Special specifications can achieve -40 ° C to 85 ° C or even wider.

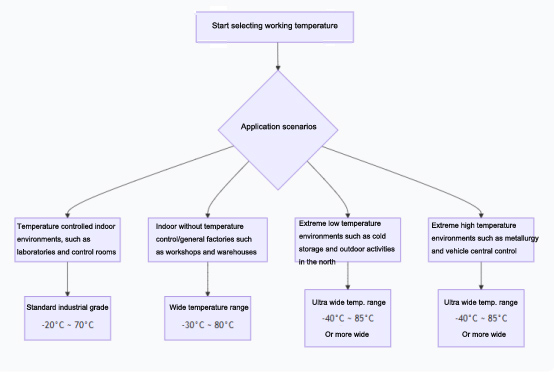

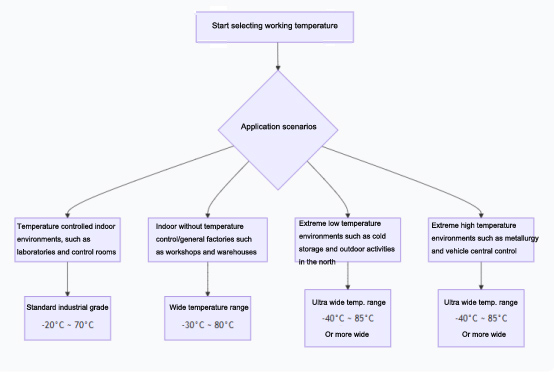

You can quickly locate your scope of needs based on the following decision flowchart:

2. In depth analysis: The impact of temperature on screens and selection strategies

Challenges and phenomena at low temperatures (usually below -10 ° C):

The response time slows down sharply: The slow activity of liquid crystal molecules leads to severe dragging and ghosting of the image.

Contrast reduction: The image appears white and the colors are dim.

Backlight startup difficulty: LED backlight efficiency decreases, brightness decreases, and even cannot be lit at low temperatures.

Liquid crystal freezing: At extremely low temperatures, liquid crystal materials may completely lose their fluidity, resulting in a black screen and potentially causing permanent physical damage.

Challenges and phenomena at high temperatures (usually above 70 ° C):

Yellowing and darkening display: Polarizers and optical films age and change color at high temperatures.

Color drift: Changes in LCD characteristics result in inaccurate color display.

Brightness attenuation: LED backlight has reduced luminous efficiency and significantly shortened lifespan at high temperatures (following the rule of halving lifespan for every 10 ° C increase in temperature).

Ghosts appear: After the screen is turned off, there are still residual images from the last displayed image.

Select strategy and corresponding scenario:

Select strategy and corresponding scenario: | Recommended Level | Explanation and Typical Scenarios |

0°C ~ 50°C | Commercial grade | Indoor environment with strict temperature control. For example, laboratories with constant temperature and humidity, data centers, and high-end medical equipment operating rooms. |

-20°C ~ 70°C | Standard industrial grade | Most industrial indoor environments without direct temperature control. For example: general factory workshops, warehouses (without extreme weather conditions), indoor power cabinets, and bank indoor ATMs. |

-30°C ~ 80°C | Wide temperature range | Factories with more stringent environments or equipment that requires outdoor start-up. For example: machine tool equipment panels without heating, outdoor communication cabinets, vehicle mounted equipment (non central control), agricultural machinery. |

-40°C ~ 85°C Or more | Ultra wide temperature range | Extreme environmental applications. Typical scenario: -Extreme cold: Terminal at the entrance of cold storage, self-service terminal in northern outdoor areas, and traffic signs in icy and snowy environments. -Extremely hot: equipment used in metallurgy, glass melting furnace workshops, vehicle mounted center consoles (which can reach temperatures above 85 ° C under summer sun exposure), and desert areas. |

3. Exceeding specifications: key technology for achieving wide temperature operation

To achieve wide temperature operation of the screen, it is not just about changing the liquid crystal material, it involves a systematic solution:

Wide temperature liquid crystal materials: This is the foundation. Specially formulated liquid crystals can maintain fast response speed and stable optical properties even at extreme temperatures.

Wide temperature LED backlight: LEDs with special packaging and materials are used to ensure normal startup and maintain brightness at low temperatures, while the light decay rate slows down at high temperatures.

Thermal management design:

Heating film: For low-temperature environments, this is the most common solution. Integrate a heating film inside or on the back of the screen, preheat the screen when starting at low temperature, and then turn on the display after reaching normal operating temperature. This is the key to achieving ultra-low temperature (such as -40 ° C) start-up.

Heat dissipation design: For high-temperature environments, the screen module will add metal heat sinks, thermal conductive silicone pads, and even utilize the device casing for heat dissipation through structural design to ensure timely dissipation of core heat.

Weather resistance of optical materials: Polarizers, brightening films, etc. need to have UV resistance, high temperature and humidity resistance to prevent aging and yellowing.

4. Common selection misconceptions and key checkpoints

Misconception 1: Only focus on the working temperature and ignore the storage temperature.

Correction: The device may also experience extreme temperatures during transportation or shutdown. Be sure to ensure

that the storage temperature range of the screen can also cover these situations, otherwise the screen may be damaged

before installation.

Misconception 2: Believing that "industrial grade" is the same.

Correction: 'Industrial grade' is a vague marketing term. Suppliers must be required to clearly indicate the specific

operating and storage temperature ranges in the specification sheet, and preferably provide third-party testing reports.

Misconception 3: Neglecting the impact of the screen's own heating.

Correction: In a sealed equipment box, the heat generated by the screen's own operation accumulates, resulting in

an actual internal temperature much higher than the ambient temperature. When selecting, the actual temperature

that the screen can withstand should be estimated based on "ambient temperature+screen temperature rise (usually

10-20 ° C)".

Key checkpoints: startup and full temperature performance.

Low temperature start-up: Inquire with the supplier whether the screen is "able to display" or "able to display normally

at full brightness" at the nominal minimum temperature? Do you need a heating film?

High temperature brightness: Inquire about the brightness attenuation of the screen at the nominal maximum temperature

(usually requiring brightness attenuation not to exceed 30% of the initial value).

Summary and Decision Checklist

Measurement environment: Accurately evaluate the minimum and maximum ambient temperatures of the device deployment

environment, and consider the temperature rise caused by poor heat dissipation inside the device.

Set goal: Add a safety margin of 5-10 ° C on top of the ambient temperature as the screen temperature range you need to filter.

Pay attention to technology: For ultra-low temperature environments, actively consult heating film solutions; For high-temperature

environments, pay attention to the heat dissipation design of the screen.

Request proof: Request detailed specifications from suppliers and request third-party wide temperature test reports, rather than relying solely on verbal promises.

Field testing: If conditions permit, conduct high and low temperature chamber testing on the sample, or conduct seasonal testing in a real environment (such as testing during the summer dog days and the winter dog days).

I hope this guide can help you make reliable choices. If you can provide specific application scenarios for the equipment (such as "cold storage barcode scanner" or "control panel next to high-temperature furnace in steel plant"), I can provide you with more targeted suggestions.

AUO LCD Display:https://www.auo-lcd.com/products/auo-lcd-screen/